Constructability reviews are imperative to project success. They can save you money, reduce the risk of cost escalation, and are often provided pro-bono by a good contractor. When it comes to requesting a contractor's constructability review, timing is important. If the review is performed too late, problems could result, including confusion surrounding the project, loss of significant time and money, and hefty change orders later in the project. The question then is: when is the optimal time to have a contractor perform a constructability review?

- Environmental

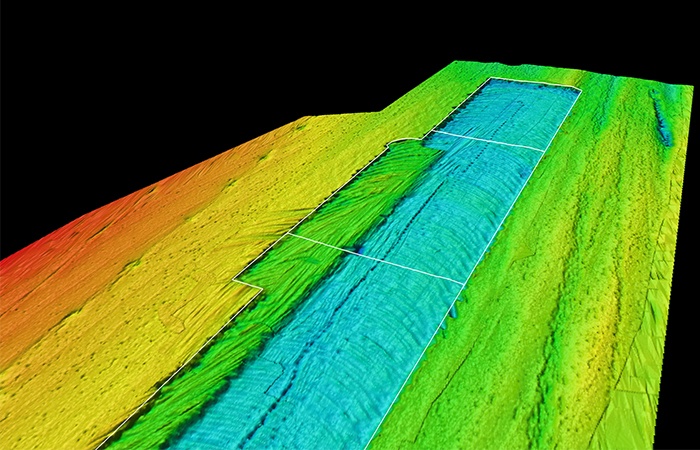

- Marine Construction

- Dam Construction

- Harbor Management

- Railroad

Newer Posts

Newer Posts