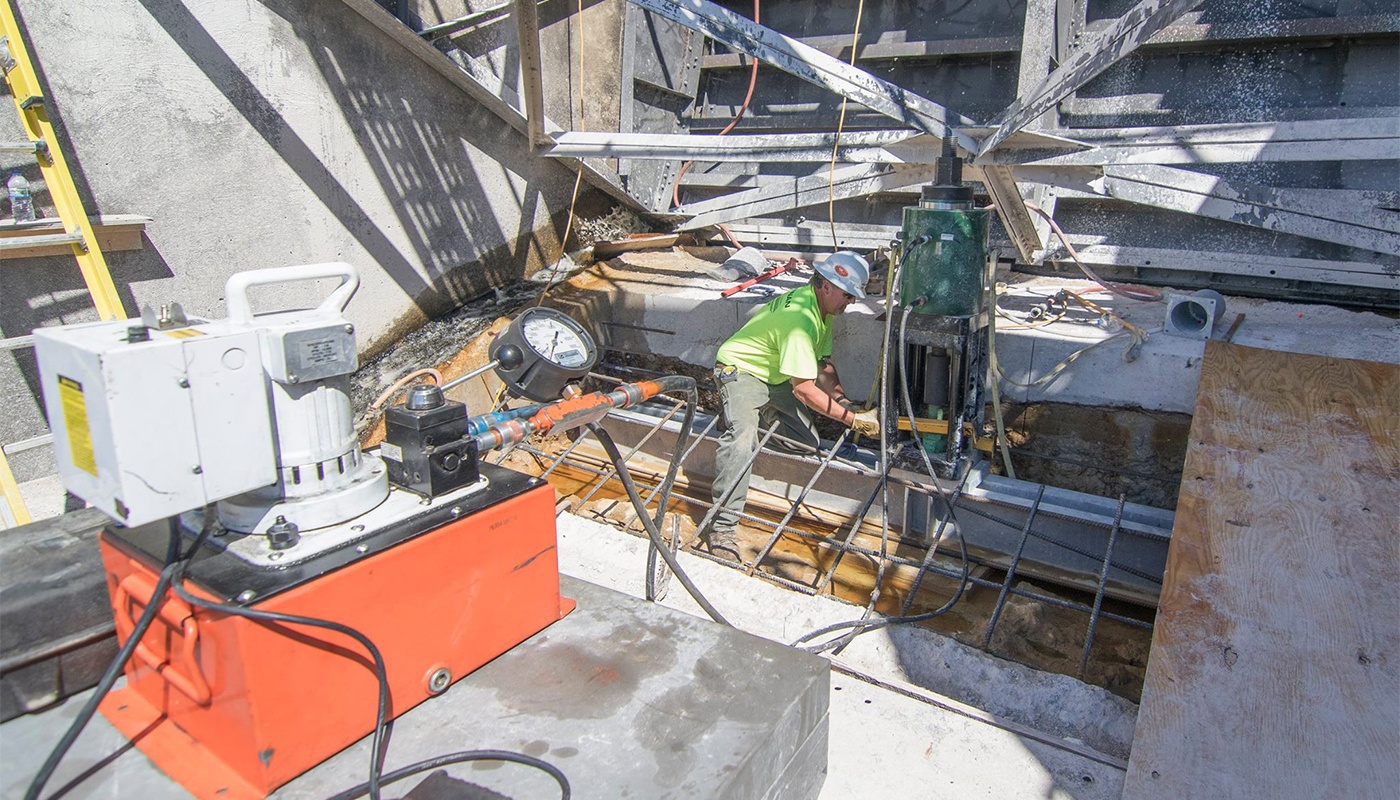

Lock and dam and hydropower infrastructure face numerous unique challenges when it comes to improving the safety and reliability of existing dams. An important structural enhancement for dam stabilization projects is the installation of high-capacity post-tensioned anchors, which may supplement or replace existing anchors.

According to the Post-Tensioning Institute, post-tensioned rock and soil anchors provide a cost-efficient, high-performance solution for projects needing both temporary and permanent stabilization solutions.

Newer Posts

Newer Posts